Mill Record Southington

RETURN TO ‘FIND MILLS’Disclaimer: Content for these properties was compiled in 2014-2017 from a variety of sources and is subject to change. Updates are occasionally made under Property Information, however the Connecticut Trust for Historic Preservation (dba Preservation Connecticut) makes no representation or warranty that the information is complete or up-to-date.

- Complex Name (Common)

- Hurwood Company

- Complex Name (Historic)

-

- Historic Industrial Complexes of Southington TR

- Hurwood Company

- Address or Location

- 379 Summer St., Plantsville, Southington

- County

- Hartford

- Historic Designation

- Associated Mill Community

- n/a

- Historic Information

Companies Associated w/Complex

- Acme Manufacturing Co. ca. 1900-ca. 1903

- Beaton & Bradley Co. 1894-ca. 1900

- Connecticut Motor Co. 1889-1893

- G.E. Wood Tool Co. ca. 1903-ca. 1910

- Hurwood Co. 1901-ca. 1903

- Stanley Rule & Level Co. ca. 1910-1920

- Stanley Works 1920-late-20th c.

- Tiger Enterprises 1982-Present (2015)

Use (Historic)

Largest Documented Workforce

50-99 (1939).

Historic Narrative

The oldest portion of the former Hurwood Company plant – as well as the block to the south formerly occupied by the Thompson Drop Forge Company factory – was originally erected by the Connecticut Motor Company in 1889. This firm was organized by R.E. Dunston and Clarence Sterling in 1888 and initially operated in Hartford, Connecticut, yet relocated to the Plantsville section of Southington following aggressive courting by the town’s Board of Trade. The Connecticut Motor Company manufactured inexpensive electric motors used in a variety of applications ranging from manufacturing to streetcar systems. Despite initial successes and promise, the firm closed its doors in 1893. The Summer Street plant subsequently passed to the Beaton and Bradley Company, a steam fitting manufacturer in 1894, and then the Acme Manufacturing Company ca. 1900. In 1901, George E. Wood, a resident of Southington, contracted with John A. Hurley, proprietor of the Acme Manufacturing Company, to produce a solid-headed screwdriver of Wood’s own design. This work took place under the Hurwood Company from 1901 until around 1903 when Hurley relocated to Bridgeport, Connecticut. Wood then formed the G.E. Wood Tool Company and continued to manufacture screwdrivers in the northern of the two manufacturing buildings erected by Connecticut Motor Company. The vast majority of Wood’s output was purchased by the Stanley Rule and Level Company of New Britain, Connecticut, a fact that kept the Southington firm’s 60 to 100 employees busy until around 1910 when Stanley Rule and Level acquired the business. Wood was kept on as superintendent of his former factory, which, under the control of Stanley Rule and Level, expanded production to include chisels, ice picks, brad awls, and screwdrivers. In 1920, Stanley Rule and Level was bought out by New Britain’s Stanley Works, however, production at the Plantsville factory continued into the late-20th century. The plant is presently occupied by Tiger Enterprises, a metal stamping firm that has occupied the factory since 1982.

- Architectural Information

Number of Existing Buildings

Roughly ten (10) adjoining primary blocks.

Dates of Construction

1889, ca. 1905, ca. 1915, 1947-1965.

Architect

n/a

Builder

n/a

Building Type

Architectural Description

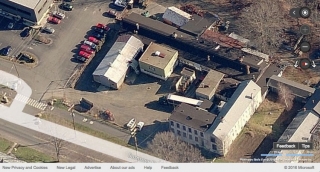

The former Hurwood Company plant is comprised of roughly ten adjoining blocks located on the east side of Summer Street, roughly 230’ north of Summer Street’s intersection with Cowles Avenue. The oldest portion of the complex was built in 1889 and is a two-and-a-half-story, 26’ x 102’ red brick manufacturing block with a raised basement level, segmental-arched window openings with stone sills, a corbelled and denticulated brick cornice, and a front-facing gable roof. The plant was enlarged ca. 1905 through the addition of a two-story, 48’ x 35’ red brick dipping and storage building adjoining the western end of the 1889 block’s north elevation; and a one-story, 26’ x 45’ forge room on the 1889 building’s east elevation. The dipping and storage building is particularly notable for its large segmental-arched window openings with stone sills and eight-over-eight double-hung wood windows, and its corbelled and denticulated brick cornice. The primary entrance to the factory was formerly located on this block’s west elevation, however, the entry stair has been removed and the doorway sealed shut. Further additions to the plant were completed ca. 1915. This included construction of one-story red brick blocks housing a boiler plant and engine room adjoining the north elevation of the 1889 building, and a one-story steel-frame forge adjoining the east elevation of the 1889 block and extending to the north. The forge measures 175’ x 42’ and has red brick and sheet metal apron walls, hopper-style windows, and a side-gabled roof with clerestory monitor. Additional one story, steel-frame manufacturing blocks were erected at the northern end of the forge’s west elevation at some point between 1947 and 1965. Both have concrete foundations and sheet metal walls. The northernmost of the two blocks measures roughly 33’ x 75’, while that to the south measures 35’ x 36’.

Exterior Material(s)

Structural System(s)

Roof Form

Roof Material

Power Source

Condition

Fair, Deteriorated

Condition Notes

The complex is in fair to deteriorated condition. The brick blocks in particular are in serious need of repairs as both their exterior walls and original double-hung wood windows have been poorly maintained.

- Property Information

-

Specific Location

Northern complex of blocks of legal parcel (379 Summer Street) totaling 2.58 acres located on the east side of Summer Street, roughly 230’ north of Summer Street’s intersection with Cowles Avenue.

See National Register application: http://pdfhost.focus.nps.gov/docs/NRHP/Text/88002681.pdf and https://npgallery.nps.gov/pdfhost/docs/NRHP/Photos/88002681.pdfAdjacent To

n/a

Exterior Visible from Public Road?

Yes

Parcel ID / Assessor Record Link

- 075023 northern blocks / Link →

Acreage

2.58

Use (Present)

- Sources

-

Form Completed By

Lucas A. Karmazinas

Date

08/17/2015

Bibliography

- List of Connecticut Manufacturers, 1922, 1924, 1930, 1932.

- Directory of Connecticut State Manufacturers, 1936, 1939.

- Industrial Directory of Connecticut, 1947.

- Register of War Production Facilities in Connecticut, 1951.

- Atlas of Hartford County, Beers, Baker & Tilden, 1869.

- Sanborn Map Company, 1890, 1895, 1901, 1911, 1923, 1947.

- Aerial Survey of Connecticut, 1934, 1965.

- The Hartford Courant, 1889, 1903, 1905.

- History of Southington, Connecticut; Atwater, Francis, 1924.

- Representative View(s)Click on image to view full file